"Zachary Oberle" (zacharyoberle)

"Zachary Oberle" (zacharyoberle)

04/19/2016 at 12:55 • Filed to: Project Hoondy, Tuning, Clutch, Motor Mounts, Flywheel, ACT

5

5

13

13

"Zachary Oberle" (zacharyoberle)

"Zachary Oberle" (zacharyoberle)

04/19/2016 at 12:55 • Filed to: Project Hoondy, Tuning, Clutch, Motor Mounts, Flywheel, ACT |  5 5

|  13 13 |

Our low-milage, one-owner Hyundai Genesis Coupe was an absolute honey on

!!!error: Indecipherable SUB-paragraph formatting!!!

; at least as far as we were concerned. Every other GenCoupe we looked at appeared to have been driven through hell, but our pristine example was cruised around by an old man and then traded in on a new Mazda 6. We were totally sure that our car would require nothing other than routine maintenance. We were smug... and wrong.

Good as new!

It started with a tail light. The passenger side rear lamp pod had sprung a leak somewhere, thus filling it with condensation. Normally an expensive PITA, but we were still under our 5 year, 60K mile standard Hyundai warranty. It was fantastic that we could make use of this as the second owner of the car, though only the first owner can benefit from the 100K mile powertrain coverage. Even still, this meant we got our absurdly expensive rear light cluster replaced for free at our local Hyundai dealer with very little fuss. No problem-o, but this was just a sign of things to come.

The headlights would come next, and this time our local dealer wasn’t so helpful. UV damage had obliterated the steeply raked headlight lenses, causing them to crack. Our dealer called this “road damage” and refused to cover it.

This started us down the long road of replacing OEM headlight lenses, as at the time whole headlamp assemblies were crazy expensive. We never completed that task and at this point the after-market has vastly improved offerings in the way of complete light pods for the Genesis Coupe. We’re currently working on a solution which we really like that will no doubt be the subject of a future article.

At this point the writing was on the wall. We knew the history of our new car. It may have been a cream-puff when the original owner was finished with it, but nearly twelve months spent sitting dormant on a dealer’s lot had done it no favors.

Of course, being a beefy sports car among a sea of practical Mazdas meant the thing was parked front-and-center the whole damn time. This was the most prominent, most exposed piece of real estate on the lot. So the car had absolutely zero shelter from sun, wind, and precipitation; while barely being driven. For a year.

Shit!

The worst was yet to come. Early in 2015 Project Hoondy began leaking brake fluid from its bell-housing; a very small, slow leak, but it was there. This could mean only one thing: our clutch slave cylinder would soon fail. After this fact became clear, we had a moment of face-palm-inducing realization.

Very early in our ownership of the car we did a full fluid replacement and bleed out on the brake system. Brake fluid is incredibly effective at absorbing water. We knew that all those months of sitting on the dealer’s lot would have caused the hydraulic brake circuit to accumulate plenty of H2O. We painstakingly and repeatedly flushed out the system with new fluid, finally topping up with high-quality DOT 4 synthetic goodness. Job done, right?

Sadly, because we are idiots, we completely spaced on the fact that the clutch’s hydraulic circuit shares fluid with the brake system. Furthermore, the clutch slave cylinder sits very low in the car’s hydraulic loop. This means water is sure to accumulate in and around the slave cylinder. Bleeding it repeatedly as well should have been an extremely high priority during early ownership of our car. We neglected that fact. It was time to pay the price.

Perhaps the clutch slave cylinder would have started leaking anyway, but we’re sure that it could have lasted longer had we not neglected it during the brake fluid change. Later dissection would confirm that the leak was caused by rusty pitting on the finely machined cylinder, causing fluid to leak past the rubber seal and into the bell-housing. Water was most definitely our culprit, which meant that we were the true cause of the problem.

Failure.

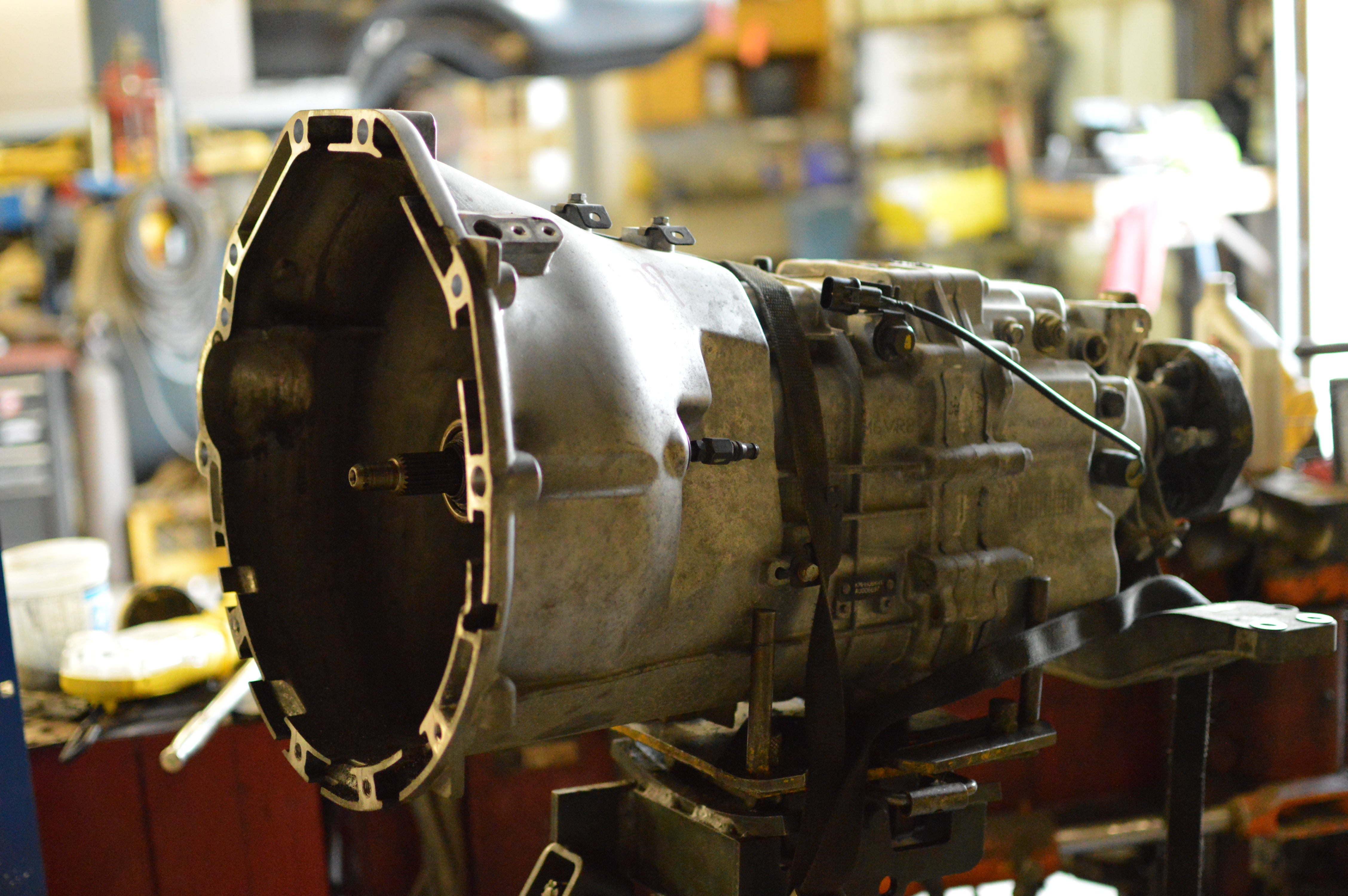

Now, what to do about it? In order to replace the slave cylinder the transmission would have to come out of the car; a huge amount of effort for a crappy little $100 part. We cringed at the thought of all that labor, putting it back together, only to have it blown apart again in a year or two when we’d finally gotten fed up enough with our dual mass flywheel to change it.

In fact, we had already looked into changing it. However, we were disappointed by the after-market flywheel offerings at the time. The only units available for the Genesis Coupe V6 were adapted universal models that did not match the OEM layout. They would physically bolt onto the car and function correctly, but they were not optimized for our drivetrain. We didn’t like the idea of this at all. We wanted a high-performance single-mass steel flywheel that was developed specifically for our platform.

©MotoIQ

ACT, one of our favorite clutch and flywheel manufacturers, had

!!!error: Indecipherable SUB-paragraph formatting!!!

a beautiful flywheel for the Turbo Genesis Coupe, but the V6 had yet to get the same treatment. Curses!

In the meantime, we’d become a bit obsessed with the sound of our car, and we were starting to think that we’d derive enough enjoyment from exhaust work to justify the cost. We had been saving up some cash to make that happen.

Meanwhile, our quest for better drivetrain mounts had begun. We slapped in a Megan Racing transmission mount which really took the edge off the inconsistent shift action during hard driving. Megan Racing also made motor mounts, but we were unimpressed with them. They were simply a firmer version of the OEM units, which were of a flawed rubber puck design. The mounting hardware consists of lame, stamped-steel cups with some ropey studs sticking out of them:

Lame.

The problem with this design is that the rubber bushing which supports the weight and resists the torque of the engine is totally un-contained in some places. This allows the engine to oscillate in any direction, which can lead to a wild build-up of momentum during hard driving conditions. Adding a firmer bushing to this type of mount is a band-aid solution at best and does little to address the real problems with the OEM design.

We decided to hold off on engine mounts. Initial inspection suggested that installing new mounts would be a time-consuming job and we didn’t want to waste said time on a mediocre product.

Our firmer transmission mount, by contrast, was very easy to install. Four bolts, ten minutes. Best of all, it took enough slop out of the drivetrain for us to no longer be concerned about breaking something. As much of a victory as this was, it still felt like an unsatisfying stop-gap solution. Over time it would continue to vex us.

There was one other aspect of the car that we knew for certain was holding it back. Our Hoondy was a Grand Touring model. We definitely preferred the suspension setup of the GT model, but it came standard with an open differential and that was just Not Cool. The car was pretty huckable considering it’s bulk, but it begged for some locking diff action so that it could be rotated with the throttle. This deficiency resulted in one mediocre slide after another, never really transitioning into that life-affirming power-oversteer goodness. We always knew this would be a problem with the car when we committed to the GT model, but living with it really made us hanker for an after-market solution.

That would all have to wait though. Our ailing clutch slave cylinder was terminally ill. We managed to nurse it along for a while with repeated bleeds to remove air along with top-ups of brake fluid. There was no stopping the impending failure though. Our slave cylinder chooched its last during an attempt to roll out of the driveway in which we had most recently performed a bleed.

Now we were up against it. The transmission had to come out of the car. We sighed heavily and ordered a new slave cylinder. Desperate to derive some extra value from the task of removing the Hoondy’s gearbox, we made an impulse-buy on a short shifter:

You don’t even need to pull the trans to get a shifter in, though it is easier.

©OS Giken

Totally bummed, we checked around different after-market vendors for clutch and flywheel options. The Genesis Coupe V6 still had limited support compared to the Turbo, though there were some super-fancy multi-disk clutch and flywheel assemblies available. We have to admit, we actually considered a balls-out $2000 OS Giken unit even though it was massively over-engineered for our needs. Stupid idea. Our search continued.

We pined after a solution from ACT. Their own website still had absolutely no mention of products for the Genesis Coupe V6. Yet, much to our surprise, we found a single online vendor who was drop-shipping brand-spanking new, V6-compatible ACT clutch and flywheel kits straight from the factory.

Salvation!

©ACT

The ACT flywheel was clearly a masterpiece even in the crappy little catalog images. It had a deep-dish, stepped design just like the Dual Mass Flywheel. The ACT unit was a single piece of forged and machined chrome-moly steel with OEM-spec ring gear and trigger ring in place. It cost a whopping $850 and we didn’t care. We had to own one.

Theoretically, because the ACT flywheel was an OEM-compatible design, our old, stock clutch friction disk and pressure plate would bolt right up to it. With about 40K miles on the clock, those parts should’ve had at least %50 of their life left in them. We could save ourselves some money and re-use the old parts...

Naaaaah!

We went all-out on our clutch rebuild, pilfering the cash we’d saved to mod the Hoondy’s exhaust. We bought a top-shelf ACT HD Street pressure plate and friction disk to go with our premo flywheel. This tacked on an extra $550. Throw in that slave cylinder, the aforementioned short-shifter, and a totally probably DOT approved braided steel clutch line. Don’t forget labor from our trusty mechanic. Add it all up and we had ourselves a pricey job on our hands.

All told, our clutch rebuild would set us back $1950. Ouch.

Was it worth biting the bullet? Find out on a !!!error: Indecipherable SUB-paragraph formatting!!! of !!!error: Indecipherable SUB-paragraph formatting!!!

!!! UNKNOWN CONTENT TYPE !!!

Niko's Work Account

> Zachary Oberle

Niko's Work Account

> Zachary Oberle

04/19/2016 at 13:05 |

|

oh dear

Brickman

> Zachary Oberle

Brickman

> Zachary Oberle

04/19/2016 at 13:09 |

|

I like that flywheel. It’s half of a truck rim :P

TheRealBicycleBuck

> Zachary Oberle

TheRealBicycleBuck

> Zachary Oberle

04/19/2016 at 13:09 |

|

It’s really disconcerting to read your posts when I have no idea who the “we” may be. You and your wife? You and your dog? You and your pet hamster?

The Dummy Gummy

> Zachary Oberle

The Dummy Gummy

> Zachary Oberle

04/19/2016 at 13:12 |

|

Wow, this was incredibly well written. Best of luck with the car.

ScoobsMcGee

> TheRealBicycleBuck

ScoobsMcGee

> TheRealBicycleBuck

04/19/2016 at 13:18 |

|

Other possibilities include:

1) Author has dissociative identity disorder.

2) Author is royalty.

TheRealBicycleBuck

> ScoobsMcGee

TheRealBicycleBuck

> ScoobsMcGee

04/19/2016 at 13:21 |

|

Given all the political correctness around these parts lately, I decided not to go there.

Klaus Schmoll

> TheRealBicycleBuck

Klaus Schmoll

> TheRealBicycleBuck

04/19/2016 at 13:22 |

|

Pretty sure it is the royal we.

ScoobsMcGee

> TheRealBicycleBuck

ScoobsMcGee

> TheRealBicycleBuck

04/19/2016 at 13:24 |

|

So the author is royalty who has DID and is working on the car with his wife, dog, and hamster.

Wait that’s worse. I’m no good at this.

Zachary Oberle

> TheRealBicycleBuck

Zachary Oberle

> TheRealBicycleBuck

04/19/2016 at 14:23 |

|

If we make it onto the front page, we’ll reveal who exactly is behind the “we”.

Zachary Oberle

> Niko's Work Account

Zachary Oberle

> Niko's Work Account

04/19/2016 at 14:25 |

|

Problem?

Zachary Oberle

> Brickman

Zachary Oberle

> Brickman

04/19/2016 at 14:31 |

|

If they made truck rims out of steel forgings, yea! It does have a slightly unusual, ‘deep dish’ design. We were used to a flywheel being a very flat object, so we were initially surprised by the wheel-like dimensions of the ACT flywheel. It all made sense once we were able to compare it with the stock dual-mass flywheel in person.

Stay tuned for an article covering the installation of all these parts.

TheRealBicycleBuck

> Zachary Oberle

TheRealBicycleBuck

> Zachary Oberle

04/19/2016 at 15:10 |

|

We swears to serve the master of the Precious. We will swear on... on... the Precious!

Frank Grimes

> Zachary Oberle

Frank Grimes

> Zachary Oberle

04/19/2016 at 19:52 |

|

we and our? who are you talking about?